Jeff Mills Contact Special Green Dont Look At The Light

Now seriously.SNIPE. Most problem I have with snipe is when I plane boards with cup or twist. The Snipe will occur regularly on cupped boards as when the second roller of a planer presses down on the board, you double the amount of pressure on the board (theoretically) pushing the cup flat with the bed. It then changes the knife contact and depth of cut across the board (which in cup would be deep in the middle and shallow on the sides) and you get SNIPE. There are many other reasons people get snipe, but on my DW735, it's the most common occurance of the issue. Solution, face-jointing.

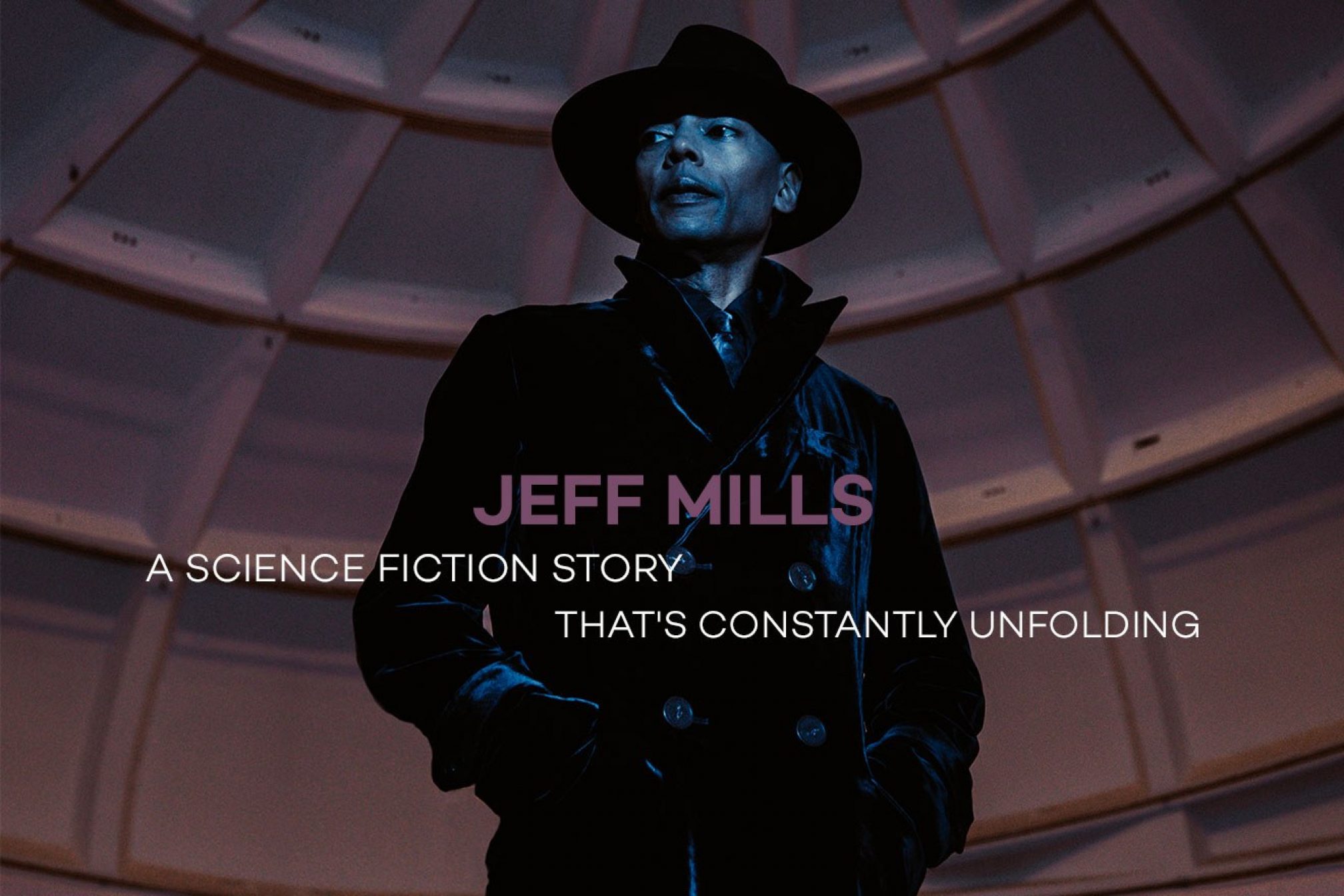

Listen free to Jeff Mills – Contact Special (Another Day in the Jungle, Belief System and more). 18 tracks (67:08). Discover more music, concerts, videos, and pictures with the largest catalogue online at Last.fm.

Problem with that, 6' jointer. Limiting my board with processing. Two solutions to that.Wider Jointer or cut stock to no wider that 5 3/4' (which is not desirable). With a properly done drum sander, you can get the majority of cup out of a board. Rather than the board moving across rollers pressing down, you are feeding a board on a belt and with the models I have used, there are no rollers pressing down before or after the drum head. So with light passes, one can 'face-joint' a cupped board with a drum sander. This is not theoretical either, I have done it.

One caviat though, heavy cupped boards render the process useless due to the amount required to be taken off to make it flat. One would end up with a very thin board. And when 'face-jointing' with a drum sander, the crown must be up. Sorry for the long post but just thought I would share some experience. :rotflm:Now seriously.SNIPE. Most problem I have with snipe is when I plane boards with cup or twist.

Don't Look Back In Anger Lyrics

The Snipe will occur regularly on cupped boards as when the second roller of a planer presses down on the board, you double the amount of pressure on the board (theoretically) pushing the cup flat with the bed. It then changes the knife contact and depth of cut across the board (which in cup would be deep in the middle and shallow on the sides) and you get SNIPE. There are many other reasons people get snipe, but on my DW735, it's the most common occurance of the issue. Solution, face-jointing. Problem with that, 6' jointer. Limiting my board with processing. Two solutions to that.Wider Jointer or cut stock to no wider that 5 3/4' (which is not desirable).

With a properly done drum sander, you can get the majority of cup out of a board. Rather than the board moving across rollers pressing down, you are feeding a board on a belt and with the models I have used, there are no rollers pressing down before or after the drum head. So with light passes, one can 'face-joint' a cupped board with a drum sander. This is not theoretical either, I have done it. One caviat though, heavy cupped boards render the process useless due to the amount required to be taken off to make it flat.

One would end up with a very thin board. And when 'face-jointing' with a drum sander, the crown must be up. Sorry for the long post but just thought I would share some experience.